In Discussion: Steel Beams Direct

Gain insights into the world of structural steel as we catch up with George Pemble, Business Development Manager at Steel Beams Direct.

From construction professionals to home renovators, uncover valuable information about steel beams and their vital role in building projects.

What sets SteelBeams Direct apart from other steel suppliers in terms of product quality and customer service?

Steel Beams direct pride ourselves on quality and service.

Reputation and integrity are two of the biggest things in business of which we strive to achieve on every order no matter how small.

All our jobs are manufactured to EN1090 UKCA Marking specification. Which is the industry standard for Steel Manufacturing. All our staff are fully qualified and are trained to a high standard.

What are some of the biggest challenges that SteelBeams Direct faces in the steel industry, and how do you overcome them?

One of the biggest challenges apart from extreme workload within our industry is quality site survey’s and fabrication drawings.

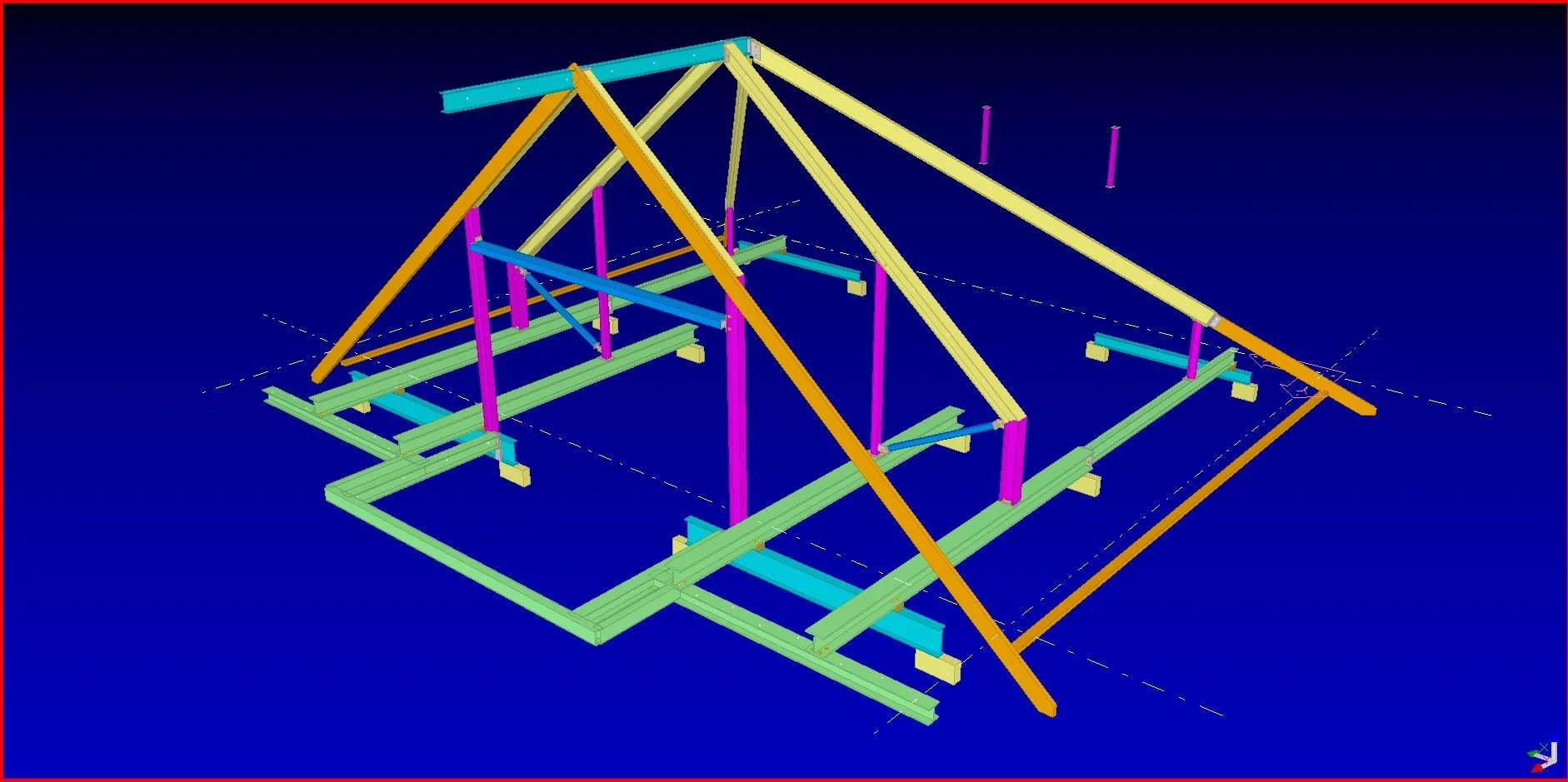

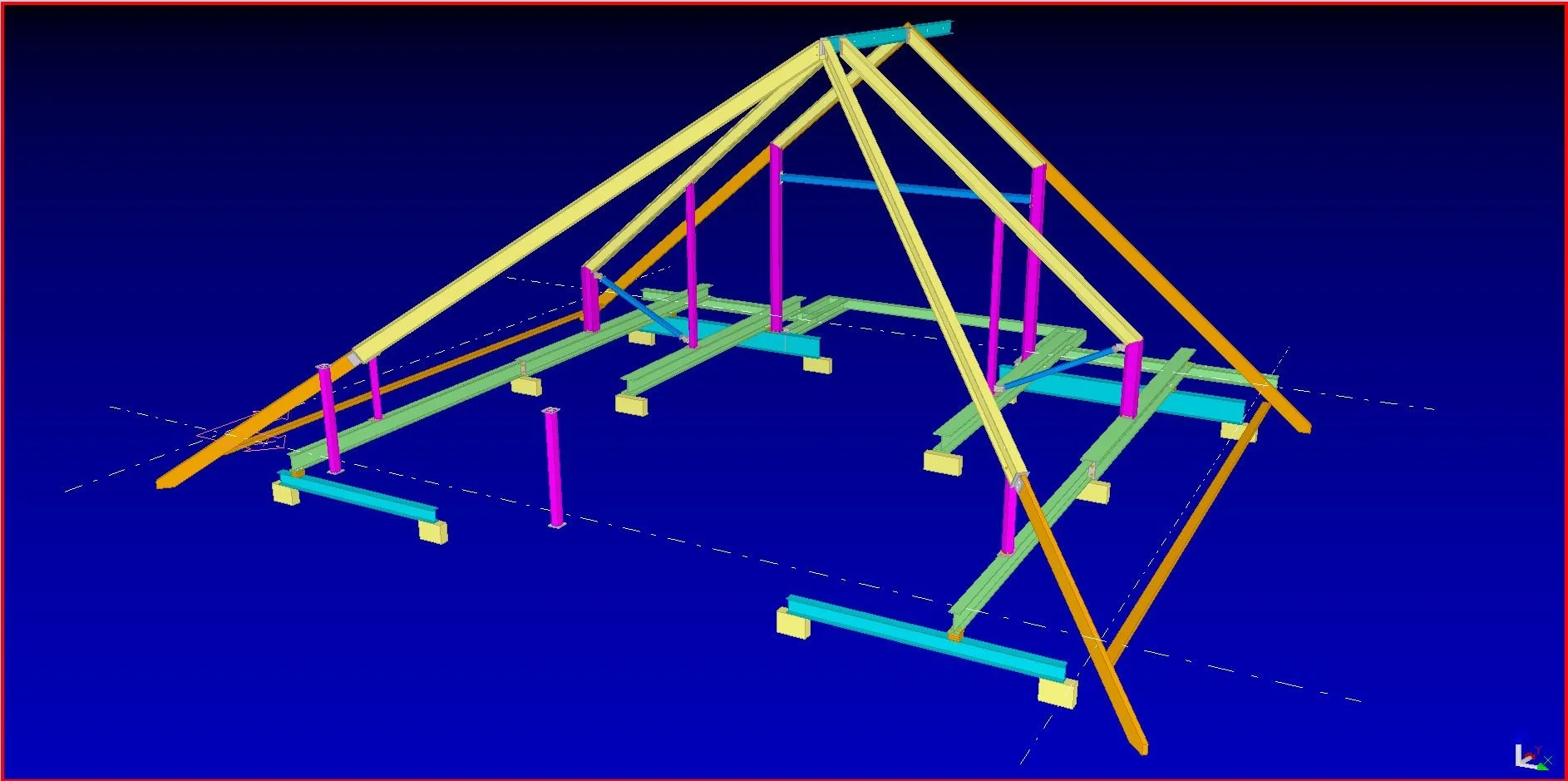

Luckily for steel Beams Direct we have two top in house and freelance draftsmen with a combined 60 years’ experience. Both using the most up to date and comprehensive CAD programs which help design the larger projects which has a whole host of benefits.

Can you tell us about any recent technological advancements or innovations that SteelBeams Direct has implemented in its manufacturing processes?

Steel Beams direct has been investing heavily over the last four years of trading. We have put in a new up to date saw line capable of handling Universal Beams and Columns up to 15.5 meters. New Lifting equipment, all new welding plants and our draftsmen use the industry leading Tekla Structures Cad program.

Could you explain the significance of being a fully UKCA Marked supplier and manufacturing to the EN1090 specification?

The sole Purpose of being UKCA Marked is to ensure a governing body has accessed you and your company to check you are manufacturing to a high standard, along with having full traceability within every product you use, sell and manufacture should there be a failure. An Audit will take place each year to ensure all new and current employee’s qualifications are still in date. And All equipment is being serviced, maintained and calibrated where required. All of which is to ensure the end product once manufactured is compliant with the current UK and European standards.

It is actually Illegal to manufacture ANY Steel product without being UKCA Marked. Whether that is on site fabrication or in house. You can have your buildings insurance revoked should you be asked to supply paper work showing your steels have been manufactured to EN1090.

If you’re planning a project that requires steel, head over to their website for all contact details.

If you’re looking to make sustainable decisions while you plan your residential project, get in touch via our form or 07510554501